Personal Account

Personal Account

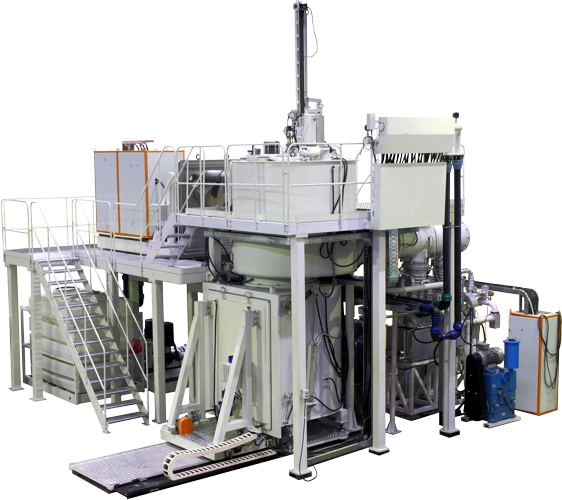

Vacuum induction casting melting plant "UVP-400"

Vacuum induction casting melting plant "UVP-400"

Description

Vacuum melting plant "UVP-400" for producing large-sized castings from heat-resistant alloys using lost wax casting

The vacuum melting plant "UVP-400" intended for manufacture of large-sized castings from heat-resistant alloys under the lost wax casting method. Melt mass from 150 to 400 kg. One melting-pouring cycle time is 2.5 hours or less.

The design feature of the plant is a two-chamber vertical design with the chambers separated by a frameless disc sealed vacuum seal with a pneumatic drive. Replacement drain funnels use heat to safely drain metal into the mold. The plant uses quick-release induction units for 150, 200, 400 kg.

The power source of "UVP-400" is the "TPCHT-600" frequency converter.

The design feature of the plant is a two-chamber vertical design with the chambers separated by a frameless disc sealed vacuum seal with a pneumatic drive. Replacement drain funnels use heat to safely drain metal into the mold. The plant uses quick-release induction units for 150, 200, 400 kg.

The power source of "UVP-400" is the "TPCHT-600" frequency converter.

Technical data

Supply voltage, V

400±10%

Rated frequency, Hz

50±1

Phases

3

Operating medium - vacuum on a cold furnace, Pa

6.65*10-1

Operating medium - vacuum during melting, Pa

6.65

Operating environment - vacuum during alloy casting, Pa

0.665 - 6.65

Leakage, l.µm.Hg/s

25

Capacity of replaceable melting crucibles (for steel), kg

150, 250, 400

Maximal angle of inclination of the melting furnace crucible, °

110

Melt temperature, °C

1750

Dimensions of the casting box with shape, mm, L*H

900*600

Vertical movement speed of the charge feeder, m/s

1/17

Speed of vertical movement of the immersion thermocouple, m/s

1/17

Installed power, kW

690

Cooling water flow (calculated per heat exchanger), m3/h

9 - 12

Overall dimensions, mm

8730*8850*7290

Noise level, dBA

80

Weight, kg

30000

Video

Submit an inquiry

Прошлое

Настоящее

Будущее

Личный Кабинет

Личный Кабинет